Chemical risk assessment made simple, fast and efficient

Automatic hazard level calculation

As soon as the SDS is imported into Quarks Safety, the hazard level is automatically calculated.

It should be noted that our methodology for rating the intrinsic hazard of the product provides for a separation of hazard scores by route of penetration.

STOT (Specific Target Organ Hazard) and CMR (Carcinogenic, Mutagenic or toxic for Reproduction) hazard levels are identified separately.

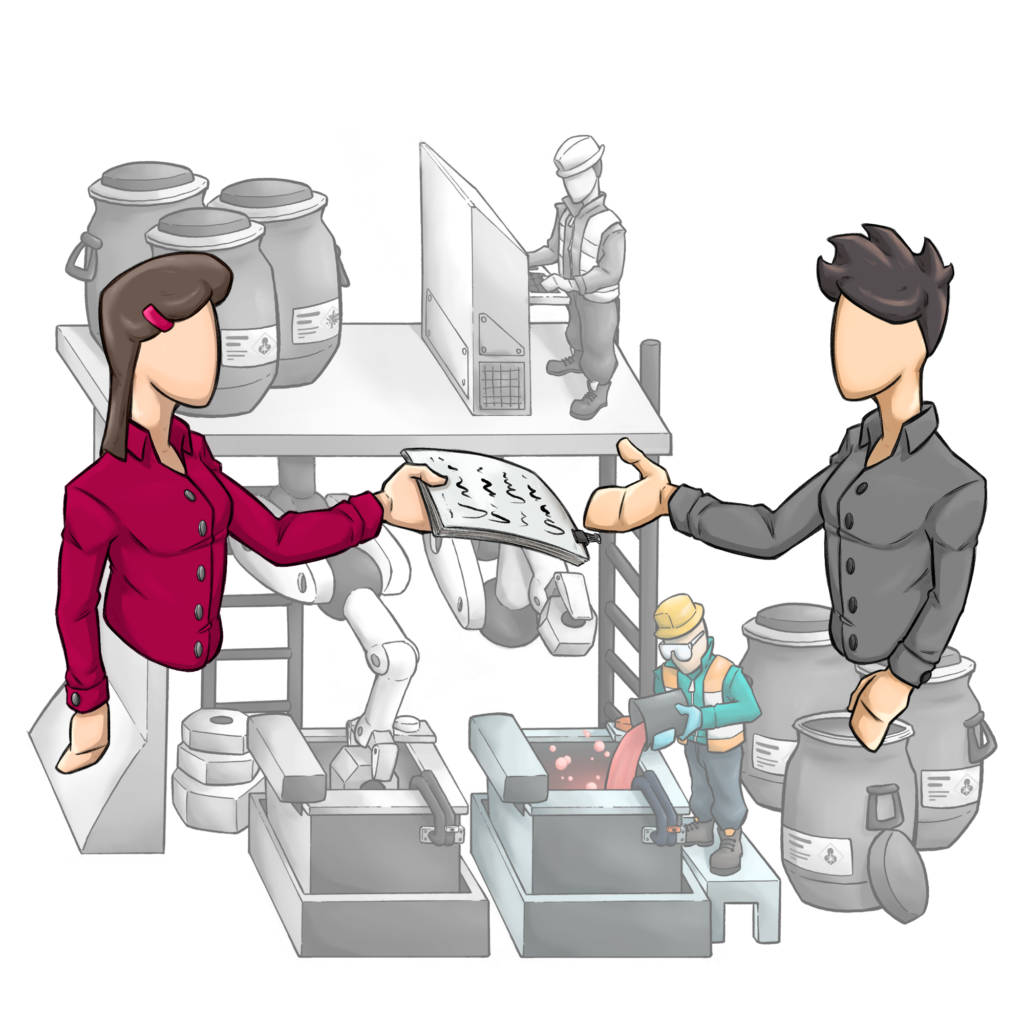

Analysis of exposure by work situation

Every use of a chemical can be identified, and the staff exposure can be assessed according to several methods.

During an initial chemical risk assessment involving several hundred or thousands of products, it may be interesting to describe the exposures in a simplified and generic way in order to obtain quickly a first risk prioritisation.

Secondly, having identified the main risks per work unit, you can activate the assessment module based on the ND2233 method transposed for CLP, or even an improved version that avoids the problems posed by the relative quantity (Qi/QMax) and other minor drawbacks of the original method published by INRS in 2005.

Improving risk management in the workplace

By identifying product hazards and analysing the conditions of each work unit using chemicals, a risk level is calculated automatically related to the enabled method.

Depending on the method selected, a risk level is proposed.

This score is a numerical indicator of raw risk, which can be used to rank uses in order to prioritize preventive actions.

After taking into account the impact of PPEs (Personal Protective Equipement) and the efficiency of organisational measures, you will get a synthetic residual risk scoring in the form of coloured smileys.

This gamification of chemical risk assessment facilitates communication towards the various stakeholders, and to obtain clear syntheses showing the progress of risk controlling within the company.

Help the sampling strategy

Mandatory OEL : Thanks to the description of the composition of chemical products and the linkage of each chemical substance to Quarks Safety’s integrated regulatory reference system, you can quickly identify chemical substances requiring mandatory control of exposure levels.

Since all work conditions involving chemicals are identified, you are able to provide at any time a sampling proposal plan to the accredited body you have selected to perform these measures, facilitating its task in developing the sampling strategy.

The french decree of December 15, 2009 defines the execution conditions of the technical controls for the occupational exposure limit values.

OEL: Occupational Exposure Limits

They are expressed as airborne concentrations of a chemical agent, for a given exposure time.